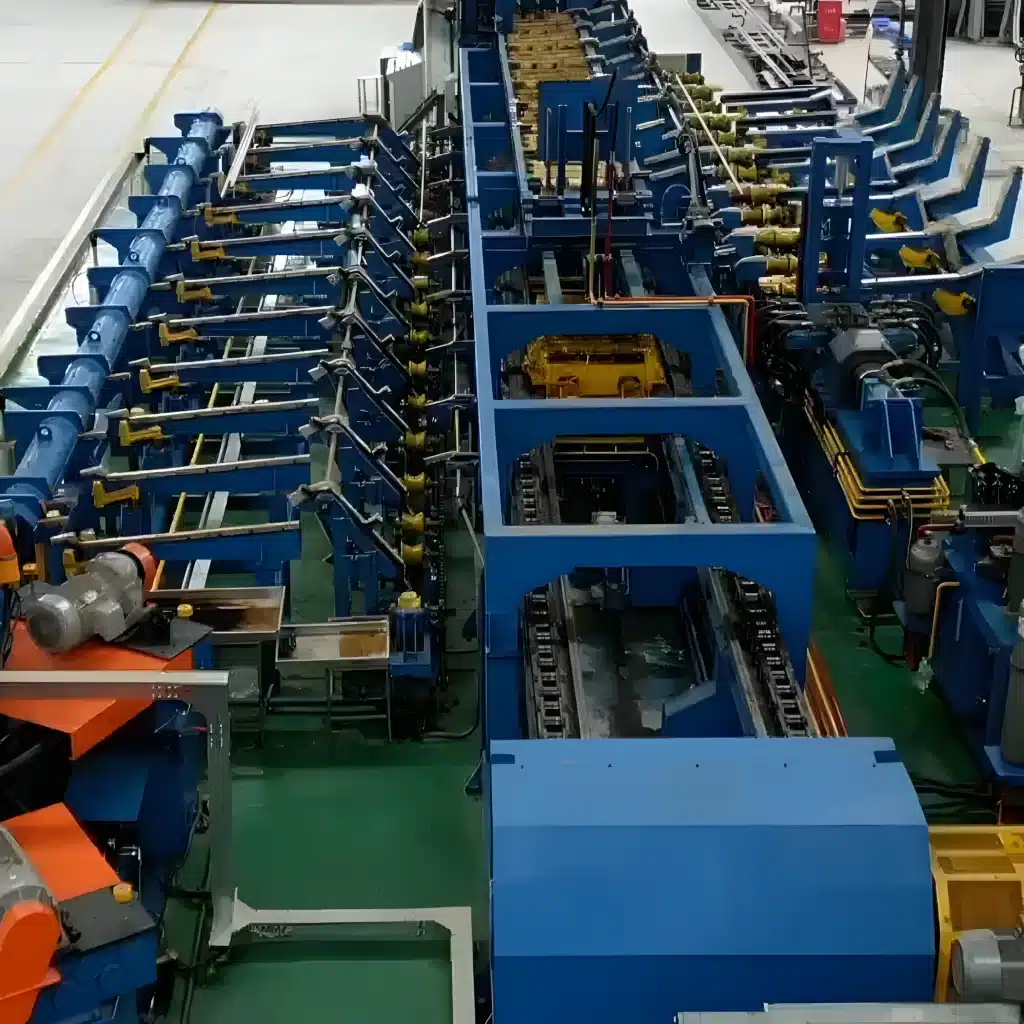

- Pipe finishing production line

- Welded pipe production line

- Deep processing production line

Seamless pipe finishing production line: exquisite craftsmanship, outstanding quality

Seamless pipes are important basic materials in industries such as petroleum, natural gas, chemical engineering, and electricity, and their quality directly affects the performance and service life of downstream products. To ensure the high quality and high performance of seamless pipes, Jinyi Machinery Equipment (Shanghai) Co., Ltd. has launched an advanced seamless pipe finishing production line. This production line integrates multiple processes including pointing, drawing, straightening, flaw detection, and sizing, ensuring that each seamless pipe meets the strictest quality standards.

Efficient automated processes

Straight seam welded pipe auxiliary machine production line: high-quality welding, fine processing

Straight seam welded pipes are widely used in construction, transportation, energy, and other fields due to their high production efficiency, low cost, and stable quality. In order to meet the market demand for high-quality straight seam welded pipes, Jinyi Machinery Equipment (Shanghai) Co., Ltd. has launched a production line for auxiliary machines for straight seam welded pipes. This production line combines advanced automation technology and strict quality control, designed specifically to enhance the production efficiency and product quality of welded pipes.

Fully automated production process

Pipe deep processing production line: efficient and precise, intelligent processing

With the continuous progress of industrial manufacturing, the processing accuracy and quality requirements for pipes are becoming increasingly high. Jinyi Machinery Equipment (Shanghai) Co., Ltd. has launched a deep processing production line for pipes, specifically designed to meet the deep processing needs of various types of pipes. This production line integrates various advanced processes such as chamfering, deburring, and robotic stacking, providing customers with efficient and precise deep processing solutions.

Precision machining and quality control

Industry Applications Solutions

Jinyi Machinery Equipment (Shanghai) Co., Ltd.

Jinyi Machinery Equipment (Shanghai) Co., Ltd. is a technology innovation enterprise focusing on "automation equipment for steel pipes" solutions. Currently, it has factories in Jinshan and Qingpu in Shanghai. The products integrate R&D, sales, production, assembly, and after-sales service. The R&D direction is positioned in the automotive, petroleum, chemical, aerospace, medical, nuclear power, construction machinery, fitness equipment, and refrigeration industries. The complete automation equipment solutions for pipe processing mainly include chipless pipe cutting beveling machines, multi-head fixed-length saws, straightening and flaw detection machines, pipe welding beveling and deburring, steel pipe stacking and bundling, double-head boring, pipe bending and shrinking, steel pipe inspection, pipe end forming, steel pipe polishing, internal punching of pipes, and weighing of steel pipes, among other automated equipment processes. The company mainly provides technical solutions, process methods, quality management, production line layout, production line equipment, personnel training, and after-sales service to customers around the above-mentioned fields and production processes.

Products we can provide for you!

We have won the trust of our customers with excellent product quality and professional services. We are committed to providing customized intelligent equipment solutions for various pipe processing enterprises, helping businesses achieve efficient production and cost optimization.

- Personalized customization solutions

- Unique design services

Zhang

Sales Director

Fully automatic chipless pipe cutting and beveling machine

Material rack technical parameters

Storage tube length: 3m-13m

Number of storage pipes: φ40 as the benchmark, can stack 100 pieces

Fixed length beveling and deburring finishing line

Technical parameters

Connection: Connection with straightening and flaw detection

flying saw: 30m/60m/min

Chamfering method: internal angle, external angle, flat

Rotary cutting fixed-length production line

Technical parameters

Cutting method: extrusion rotary cutting

Cutting method: chipless cutting

Cutting range: φ20mm-φ75mm

Cutting thickness: 1mm-6mm

Fixed length: 3m-12m (2 times size - 3 times size)

Cutting precision: ≤5mm

Material feeding: multiple material storage

Straightening, flaw detection, sizing, stacking, bundling, weighing, finishing production line

Technical parameters

Length 4000-12500mm

Diameter 10-76mm

Wall thickness 1-12mm

Bundle package size: 350-600mm

Weighing range: 0.3T-5T

Consulting hotline

+8613818318236

We always adhere to the concept of "innovation, quality, and service" to provide customers with comprehensive support and assurance. We not only manufacture equipment but also offer overall solutions for intelligent production.

Jinyi Machinery Pipe Smart Equipment!

We firmly believe that technological innovation is the driving force behind industry development. Our professional team is always at the forefront of exploration, creating greater value for our clients.

- Strict quality control system

- Continuous technological innovation

- Customized solutions

- Worry-free service support throughout

- Efficient cost optimization

- Internationally leading manufacturing technology

10

Years

Industry experience

Mission Everything is for your satisfaction!

We are committed to intelligent and automated solutions,

Improve the efficiency and quality of pipe processing.

Customer satisfaction

We provide comprehensive pre-sales and after-sales services, achieving a customer satisfaction rate of over98%earning consistent praise and long-term trust from our clients.

Research and development investment rate

We invest 15% of our annual sales revenue into research and development, continuously introducing forward-looking intelligent solutions to lead the development of the industry.

Product qualification rate

We use the most advanced manufacturing processes and strict quality control to ensure the precision and stability of each device, allowing our customers' product qualification rate to reach over 99.5%.

Cooperative Partner

Contact & Us

We firmly believe that technological innovation is the driving force behind industry development. Our professional team is always at the forefront of exploration, creating greater value for our clients.

Shanghai Jinshan (Head Office):

No. 6363 Zhu Lü Road, Lüxiang Town, Jinshan District, Shanghai

Shanghai Qingpu (branch):

No. 6363 Zhu Lü Road, Lüxiang Town, Jinshan District, Shanghai

Contact number :

Telephone : +86 021 57271078,

Mobile : (+86) 13818318236

Email address :

jyjx@jinyimech.com

Consult immediately!

Are you looking to understand the quotation, design, or other solutions?

We will provide integrated services.